- Engineering

Consulting - Mineral

Processing Test - Mines

Design - Equipment

Manufacture - Installation & Commissioning

- Personnel

Training - Designed Capacity Reached

Mineral Dressing Test

Mineral dressing test is in charge of Mineral Dressing Research Institute belonging to our Company

I Preparation before test

The clients should provide about 50g representative samples, some special samples about 200~1000g. The simple test needs 30 working days, and the detailed test about half a year.

Sign the test contract with clients before the mineral dressing test, and make sure dressing process to test

II Testing process

1. Chemical Lab of Mineral Dressing Research Institute analyzes the material components (ore structure, mineral and types of ore) and chemical properties (elements, the particle size screening, density, ore relative grindability) of crude ore, and gets some data for the subsequent beneficiation test.

2、After the working of Chemical Lab, Mineral Dressing Research Room takes the mineral beneficiation test which tests the optimum conditions of dressing process. Testers take the exploratory testing at first relying on rich experience, and then the detailed testing including grinding fitness, reagent dosage, open and closed circuit test, etc. After obtaining the final products,testers should analyze them to get the recovery rate, and then takes sedimentation test of concentrate and tailings as references of equipment selection.

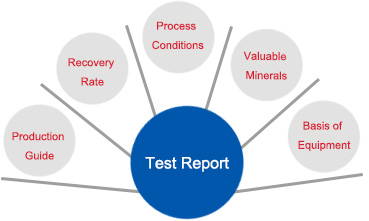

III Test results

After finishing all the tests, Mineral Dressing Lab writes a detailed “Mineral dressing test report” by summarizing the test process. In the last part of test report, the optimum technological process and technological parameters are presented.

"Mineral dressing test report" is important basis of next mine design, and brings significance of guiding actual production.

Notes: Recovery rate is the final result of mineral dressing test, and the core of dressing plant construction. Every 1% reduction of recovery rate cause huge losses, especially in gold, silver mine, so the purpose of mineral dressing test is to get the recovery rate as high as possible in order to reduce the loss of clients.

Mineral Dressing Research Institute

Mineral Dressing Research Institute belonging to our company is divided into Mineral Dressing Research Room and Chemical Room. Mineral Dressing Research Room is responsible for mineral dressing test; the Chemical Lab for the chemical composition analysis of crude ore, products (intermediate products, final products) and other samples.

The expert teams of Mineral Dressing Research Institute consist of the professionals who enjoy government special allowance of the State Council or retired from University. Mineral Dressing Research Institute could independently contract foreign projects, and mainly carries on the research of gold, non-ferrous metal, and ferrous metal. The number of projects carried on every year is about 60.

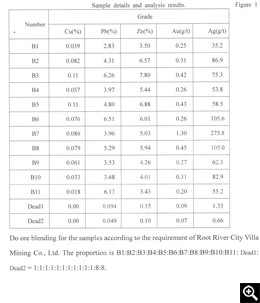

Each dressing test of Mineral Dressing Research Institute is in strict accordance with the following steps (the following table data is from the relevant dressing test data of a client)

Various specifications of floatation test equipment

Various specifications of floatation test equipment

Specimen of ore

Specimen of ore

Spiral chute (experiment use)

Spiral chute (experiment use)

Sampling in the cyaniding process

Sampling in the cyaniding process

Cyaniding leaching test of gold sample

Cyaniding leaching test of gold sample

Combustion sulfur testing device

Combustion sulfur testing device

Tester is working

Tester is working

Crusher (experiment use)

Crusher (experiment use)

Cone ball mill (experiment use)

Cone ball mill (experiment use)

Sedimentation test

Sedimentation test

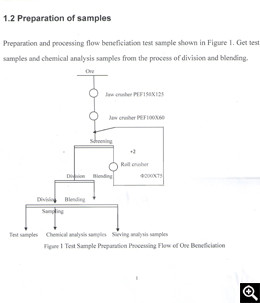

I Preparation of sample

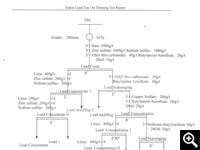

This part is described as preparation of sample used in test. The following sample process flow chart and preparation table is provide for clients

Sampling and processing flow chart of crude ore of mineral dressing test Sampling and processing flow chart of crude ore of mineral dressing test |

Test sample details and analysis results Test sample details and analysis results |

| Sampling and processing flow chart of crude ore of mineral dressing test | Test sample details and analysis results |

II Crude ore properties determination

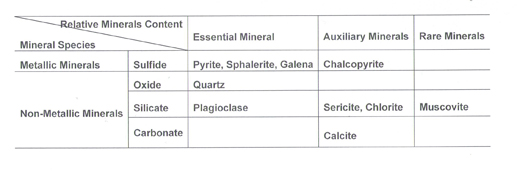

The crude ore properties determination includes: ore material component determination and ore chemical properties determination

1. Ore material component determination

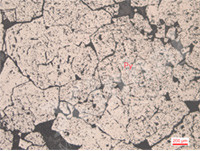

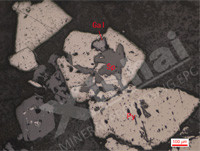

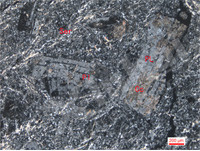

The ore material component determination includes instruction, types and components of ore, metal and non metal mineral characteristics. The following part of chart presents the ore material component determination

Iron pyrite

Iron pyrite

Iron pyrite

Iron pyrite  Iron pyrite

Iron pyrite  Porphyritic texture

Porphyritic texture  Quartz vein

Quartz vein

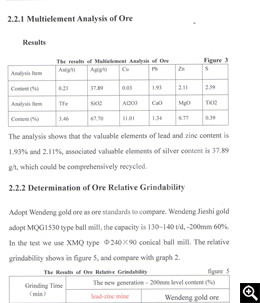

2. Ore chemical properties determination

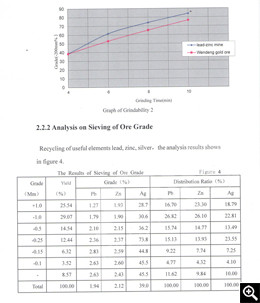

Ore chemical properties determination includes crude ore multi-element analysis (to make sure the ore if comprehensively recycled and used), crude ore particle size screening analysis, ore density determination and ore relative grindability test. The following is related charts of ore tests

Results of crude ore multi-element analysis and relative grindability test Results of crude ore multi-element analysis and relative grindability test |

Grindability curve and crude ore particle size screening analysis results Grindability curve and crude ore particle size screening analysis results |

| Results of crude ore multi-element analysis and relative grindability test | Grindability curve and crude ore particle size screening analysis results |

III Mineral dressing test

Mineral dressing test includes exploration test and mineral dressing conditions test

Exploration test primarily explores the mineral dressing conditions, and then gets better process condition. The detailed test follows the process condition determination including grinding fineness test, reagent test, open circuit and closed circuit test. The following is part of the chart of exploration test and detailed test for customers.

Flotation exploration test flow chart Flotation exploration test flow chart |

Grinding fineness test flow Grinding fineness test flow |

Reagent dosage test Reagent dosage test |

Open circuit test result and closed circuit result Open circuit test result and closed circuit result |

| Flotation exploration test flow chart | Grinding fineness test flow | Reagent dosage test | Open circuit test result and closed circuit result |

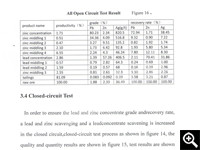

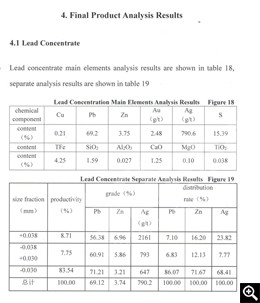

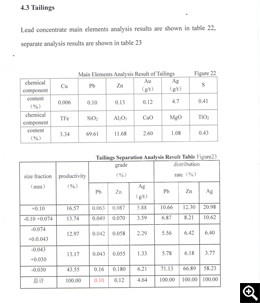

IV Final analysis result

This step takes the valuable element analysis and screening analysis of valuable mineral concentrate and tailings, and gets the recovery rate of valuable mineral

Main elements analysis result of Pb concentrate Main elements analysis result of Pb concentrate |

Main elements analysis result of tailings Main elements analysis result of tailings |

| Main elements analysis result of Pb concentrate | Main elements analysis result of tailings |

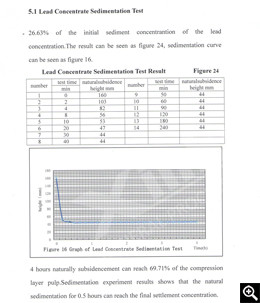

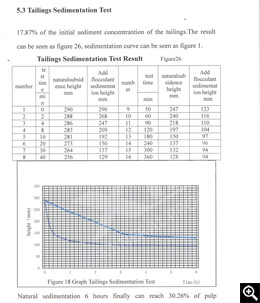

V Sedimentation test

Sedimentation test as reference of equipment selection aims to concentrate and tailings of valuable mineral. The flowing is the sedimentation test result of Pb concentrate

Pb concentrate sedimentation test result and sedimentation curve Pb concentrate sedimentation test result and sedimentation curve |

Tailings sedimentation test result and sedimentation curve Tailings sedimentation test result and sedimentation curve |

| Pb concentrate sedimentation test result and sedimentation curve | Tailings sedimentation test result and sedimentation curve |