- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

- Cases

- News

- Contact Us

Home > Products > Hydrocyclone>Hydrocyclone

Hydrocyclone

- Product Introduction

- A cyclone with involute feeding

- Capacity

- Capacity≤542m3/h

- Product Improvement

- Unique involute feeding eliminating the disturbance, reduces wear and improves the classification efficiency

Advantages

The way of involute feeding through the inlet branch reduces the turbulence of the burst emanative flow when materials entry, makes a smooth movement of liquid inside cyclone, therefore gives a sharp classification.

The rational length proportion of column and cone and reasonable insert depth of vortex finder

Wear – resistant rubber as liners prolongs the service life by 2-4 times

3D Exploded Video

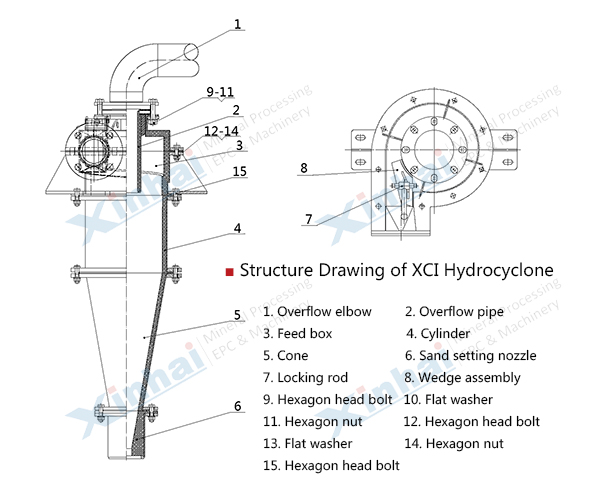

Every single part and working principles of Hydrocyclone are showed in Yantai Group 3D video, which is really convenient for you to see the structure and working principles of those large equipment.

Product Features

Yantai Group hydrocyclone with unique structure design adopts the composite structure of multi section type column body. It changes the height of column according to the need. If the height increased, overflow fineness increase up to about 10 μ m diameter. Each diameter has unique cylinder length and cone angle, which can achieve the maximum tangential velocity at the minimum total cyclone length, so as to increase centrifugal force and improve the classification efficiency.

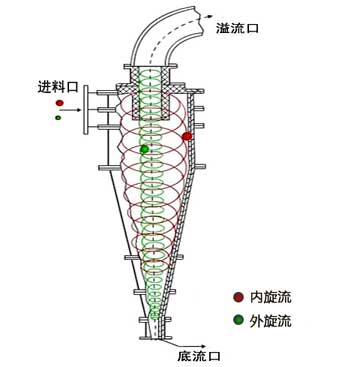

Work Principle

The working principle of Yantai Group hydrocyclone is centrifugal sedimentation, when two phases (or three phases) mixed liquid is fed into hydrocyclone by a certain pressure liquid and produces strong three-dimensional-elliptic rotational movement. Due to the different density of particles, the centrifugal force, the centripetal buoyancy and drag force is different. So most coarse particles (or heavy phase) are discharged from cyclone underflow outlet, and the fine particles (or light phase) from the overflow tube, so as to achieve separation.

Product Structure

Working modes of Yantai Group hydrocyclone includes classification, condensation, dehydration, desliming, sand removing sand, washing, ultrafine classification etc.

Technical Parameters

| Model | Spec. | Processing Capacity (m3/h) | Partition Size (μm) | Diameter of Overflow Port (mm) | Diameter of Dust- Setting Nozzle (mm) | Inlet Pressure (MPa) |

| XC II F 150 | 150 | 10 ~23 | 25 ~74 | 30 ~50 | 8~22 | 0.06~0.15 |

| XC II F 200 | 200 | 17 ~38 | 28 ~80 | 40 ~65 | 16 ~32 | |

| XC II F 250 | 250 | 24 ~53 | 30 ~82 | 65~100 | 16 ~40 | |

| XC II F 300 | 300 | 40~100 | 36 ~90 | 65~120 | 20 ~40 | |

| XC II F 350 | 350 | 56~118 | 40~100 | 80~120 | 30 ~70 | |

| XC II F 375 | 375 | 74~157 | 42~105 | 90~135 | 30 ~70 | |

| XC II F 450 | 450 | 90~192 | 44~110 | 100~150 | 30 ~70 | |

| XC II F 500 | 500 | 128~300 | 50~115 | 130~220 | 35~100 | |

| XC II F 550 | 550 | 155~368 | 52~120 | 140~240 | 35~100 | |

| XC II F 600 | 600 | 200~468 | 57~125 | 160~260 | 65~110 | |

| XC II F 660 | 660 | 237~524 | 60~130 | 180~280 | 80~150 |

Related Products

Tel: 0086-153-1182-6627

E-mail: mhxu@xinhaimining.net