- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

- Cases

- News

- Contact Us

Home > Products > Magnetic Equipment>Magnetic Separator

Magnetic Separator

- Introduction

- A wet permanent magnetic separator for separating strong magnetic minerals

- Capacity

- 8-240t/h

- Product Improvement

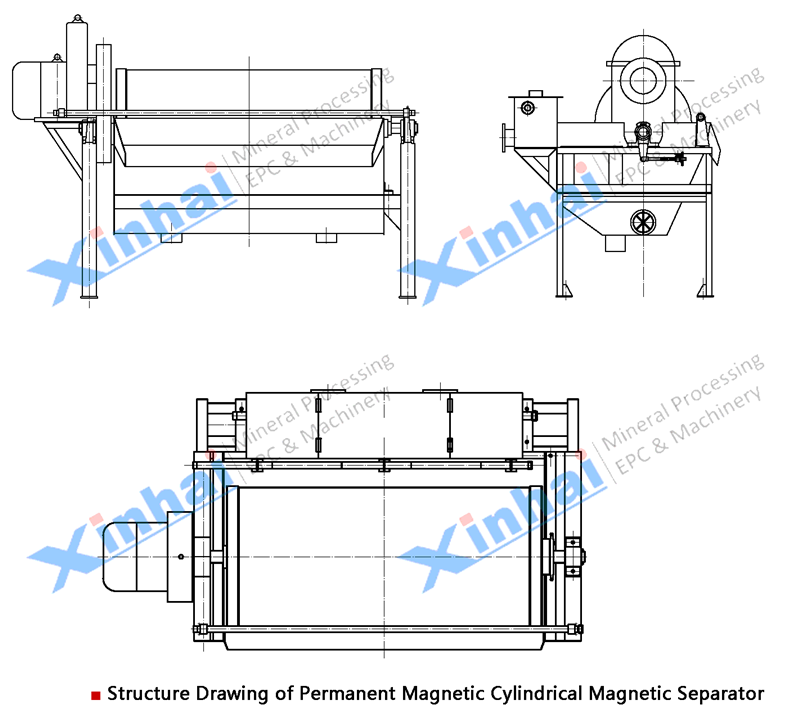

- Magnetic system materials adopt ferrite and NdFeB with high performance, high coercive force and high remanence; the surface of the cylinder is lined with Yantai Group wear-resistant rubber.

Advantages

Magnetic system is compounded of ferrite and permanent magnets; the average magnetic induction intensity of cylinder surface is 100~600mT

The same cylinder can be equipped with three types of tank adapting to different dressing process.

Small area taken, good separation for magnetic mineral, reduce the load of next process

3D Models

Please wait patiently in case the slow loading speed, for Yantai Group 3D model must let you have a more intuitive understanding of our product.

Product Introduction

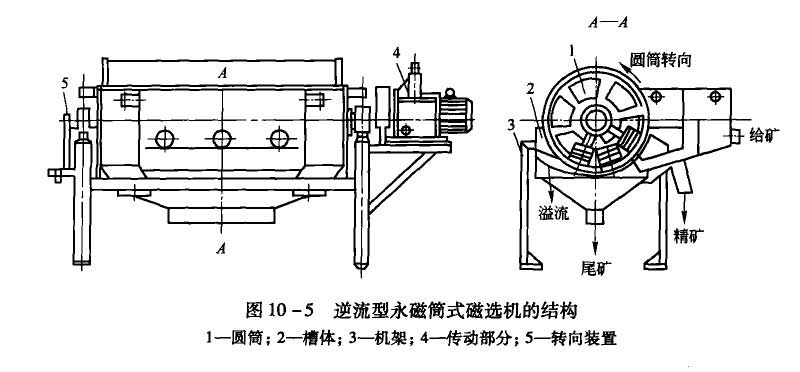

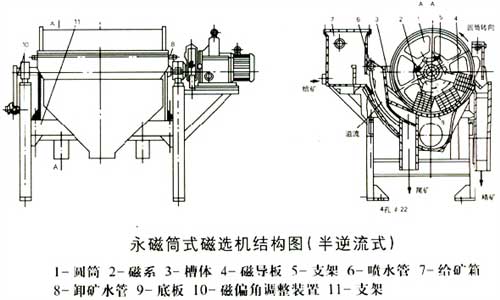

Permanent magnetic drum separators have 3 kinds including downstream type, counter flow type and semi- counter flow type according to the difference of base structure.

Downstream type permanent magnetic drum separator: slurry flows in the same direction with drum

Counter flow type permanent magnetic drum separator: slurry flows over against drum, which create great conditions for cleaning of non magnetic ores. The non magnetic ores approach the clean surface of drum and the magnetic ores can be absorbed in the strongest magnetic field.

semi-counter flow type permanent magnetic drum separator: slurry is fed into cavity from the bottom of drum, and the magnetic ores fall into concentrate tank after reaching a certain height, while the non magnetic ores will enter into tailings tank along with slurry in the opposite direction with drum.

Product Application

This machine is widely used in mineral processing, coal washing and chemical industries for strong magnetic minerals that wet classification size ranges from 0 to 6 mm, and divides the minerals into magnetic and non-magnetic materials. It often processes strongly magnetic materials such as magnetite, magnetic pyrite etc..

Technical Parameters

| Model & Spec. | CTBY1018 | CTBY1024 | CTBY1030 | CTBY1218 | CTBY1224 | CTBY1230 |

| Diameter of Cylinder (mm) | 1000 | 1000 | 1000 | 1200 | 1200 | 1200 |

| Length of Cylinder (mm) | 1800 | 2400 | 3000 | 1800 | 2400 | 3000 |

| Surface Magnetic Density (mt) | 350~550 | 350~550 | 350~550 | 350~550 | 350~550 | 350~550 |

| Rotating Speed of Cylinder (r/min) | 23 | 23 | 23 | 20 | 20 | 20 |

| Capacity of Dry Ore (t/h) | 42 ~65 | 53 ~86 | 82~124 | 58 ~97 | 71~120 | 103~158 |

| Feed Size (mm) | 0~10 | 0~10 | 0~10 | 0~10 | 0~10 | 0~10 |

| Slurry Density (%) | 20 ~50 | 20 ~50 | 20 ~50 | 20 ~50 | 20 ~50 | 20 ~50 |

| Motor Power (kW) | 5.5 | 7.5 | 7.5 | 7.5 | 11 | 11 |

| Total Weight (t) | 5.2 | 6.4 | 7.1 | 6.7 | 7.2 | 8.9 |

| Equipment Length (mm) | 3160 | 3790 | 4460 | 3380 | 4190 | 4770 |

| Equipment Width (mm) | 2250 | 2250 | 2250 | 2460 | 2460 | 2460 |

| Equipment Height (mm) | 1750 | 1750 | 1750 | 2000 | 2000 | 2000 |

Related Products

Dry Separator with Eccentric Rotating Magnetic System | Magnetic Separator | Magnetic Drum |

Tel: 0086-153-1182-6627

E-mail: mhxu@xinhaimining.net