- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

- Cases

- News

- Contact Us

Home > Products > Magnetic Equipment>Dry Separator with Eccentric Rotating Magnetic System

Dry Separator with Eccentric Rotating Magnetic System

- Introduction

- A Yantai Group self-developed patent products - Dry Magnetic Separator

- Capacity

- ≤150t/h

- Product Improvement

- This patent products is newly developed by Yantai Group, and patent application is No.: 201410328639.2. Compared to conventional cylinder and dry magnetic separator, this patented product solves the eddy current heating problem, ore sticking problem for separation cylinder, and mine unloading problem of conventional 360 degree rotating magnetic dry separator.

Advantages

1, This patented product is a kind of upgrading equipment based on conventional magnetic roller or conventional dry separator. When it is working, the magnetic minerals will take rapid magnetic reversal and magnetic agitation, which will significantly reduce the number of non-magnetic (weak magnetic) minerals in the magnetic minerals. In this way, the efficient separation of magnetic minerals and non-magnetic (weak magnetic) minerals will be realized, and fine magnetic minerals and coarse magnetic minerals will not get lost.

2, This patented product solves the eddy current heating problem, ore sticking problem for separation cylinder, and mine unloading problem of conventional 360 degree rotating magnetic dry separator. The conventional 360 degree rotating magnetic dry separator must use the belt to unload the mine by the outside of it, therefore the magnetic minerals are easy to enter the central space between the inside belt and sorting tank. The magnetic minerals attached on the surface of sorting tank cannot fall off automatically (cannot unload mine automatically). As the accumulation grows, the separation effect is affected. What's worse, rapid wear of sorting tank body as well as the belt will be caused, and the normal operation of production will be seriously affected.

3, Under the condition that the grade of the dry tailings is equal to or even lower than that of conventional magnetic roller or conventional dry separator, for high-grade and lean magnetite with different features, by adjusting corresponding technical parameters and structure, about 10%-30% tailings discharging and about 1.0%-8.7% of concentration grade can be increased compared to conventional magnetic roller or conventional dry separator. The concentrate grade of dry separation is significantly enhanced compared to the feeding grade. Under the conditions of fine crushing size of below 2 mm and coarse dissemination size, more than 60% grade of the dry separation concentrate can usually be obtained directly. In the actual production, if one patented product can process 1 million tons of raw ore every year (150 t/h, 1million t/a), it can discharge an extra 0.1-0.3million tons of the qualified dry tailings, and reduce 0.1-0.3 million tons of waste rocks before ore grinding every year, which can reduce the concentration ratio and the cost of production sharply. If the production costs such as the ore grinding, magnetic separation and the wet separation tailing processing is 30 yuan/ton, one set of the patented product can save the production costs of about 3-9 million yuan. Under the condition of the same amount of mining, the output of the iron concentrate basically remains unchanged.

4, As the amount of the waste rocks into the mill is reduced, the annual capacity of the ball mill is actually increased by (100,000-300,000 t/a) for one patented product, and the iron powder production is correspondingly increased without any investment in plant expansion, increase of grinding and mineral processing equipment, roads, water supply, tailing processing, etc., and with almost no increase of electricity load and labors, the economic and resource environmental benefits are significant.

5, Before grinding, a large number of qualified dry tailings can be discarded, with the convenient treatment, they can be directly transported to the hillock, and also can be used as building stones or river sand to create certain economic benefits, while by which the number of wet tailings are reduced and the lifespan of tailings pond is improved. The magnetic wrapping angle is 360 degree. The magnetic systems all adopt Nd-Fe-B magnets with high magnetic energy product and high coercivity, strong magnetic density and high affect depth. The demagnetization rate of the magnetic density within 8 years is no more than 5%.

6, Covering the magnetic system with non-magnetic stainless steel ensures no peeling off of the magnet.

7, The separation cylinder is covered with the super wear-resistant rubber produced by our company, thus the service life can be prolonged significantly.

Work Principle

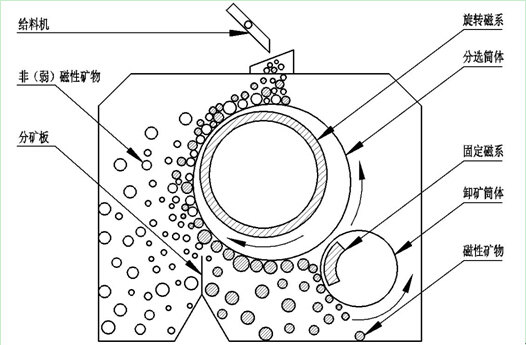

As shown in the figure, the separation cylinder without belt outside will enhance the intensity of magnetic field of the separation area. The rotating magnetic system (wrap angle of 360 degree) is set inside the separation cylinder, while the fixed magnetic system (magnetic wrapping angle of less than 90 degree) is set inside the ore dumping cylinder. The rotation direction of the separation cylinder is as the same as that of the ore dumping, but is opposite to that of the rotating magnetic system.

When the materials feeder transports the minerals to the separation area of the separation cylinder, the magnetic minerals will alternate rapidly and repeatedly within a short time through the N pole and S pole of the magnetic field, and the magnetic minerals will do magnetic reversal and magnetic agitation. The non-magnetic (weak) magnetic mineral mingled in the magnetic minerals is not or slightly affected by the adsorption of the magnetic force, moving to the outer layer gradually, and is thrown out by the centrifugal force, gravity and the joint action of magnetic turn and agitation of magnetic minerals.

In the separation area of the separation cylinder, the centrifugal force and gravitation of magnetic minerals mingled with non-magnetic minerals are much less than the magnetic force. With the adsorption of the magnetic force and the joint action of the magnetic turn and agitation of magnetic minerals, the magnetic minerals will move to the inter layer gradually. When the magnetic minerals rotate to the ore unloading area with the separation cylinder, as the rotation magnetic system is eccentric, the magnetic density of the ore unloading area for the separation cylinder is extremely weak, and most of the magnetic minerals can fall off automatically. A small quantity of magnetic minerals not falling off will be adsorbed to the external surface of the ore unloading cylinder with higher magnetic density when rotating to the position nearby the ore unloading cylinder so as to realize the automatic unloading of magnetic minerals.

Product Application

To be applied to the dry preconcentration of high-grade and lean magnetite ore before grinding with the selected granularity below 30mm. The finer the granularity is, the better the result is. Generally, large amount of tailings can be discharged, and the grinding quality can be greatly enhanced. To be applied to dry separation and recycling of the lost magnetite from the abandoned tailings. To be applied to dry separation and recycling of ferromagnetic materials from the abandoned steel slag.

Technical Parameters

| Model & Spec. | CTXG-0606 | CTXG-0812 | CTXG-0818 |

| Diameter of Cylinder (mm) | 600 | 800 | 800 |

| Length of Cylinder (mm) | 600 | 1200 | 1800 |

| Surface Magnetic Density (mt) | 300~500 | 300~500 | 300~500 |

| Feed Size (mm) | -30 | -30 | -30 |

| Feed Moisture Content | < 5% | < 5% | < 5% |

| Capacity (t/h) | < 35 | < 100 | < 150 |

| Motor Power (kW) | 5.5X2 | 11X2 | 11X2 |

| Total Weight (t) | 2.9 | 5.8 | 7.9 |

| Overall Dimension (LXWXH) (mm) | 2700X1700X1900 | 3400X2000X2100 | 4200X2000X2100 |

Related Products

Dry Separator with Eccentric Rotating Magnetic System | Magnetic Separator | Magnetic Drum |

Tel: 0086-153-1182-6627

E-mail: mhxu@xinhaimining.net