- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

- Cases

- News

- Contact Us

Home > Products > Dewatering Machine>Press Filter

Press Filter

- Product Introduction

- A dewatering equipment relying on pressure of slurry pump including chamber press filter and plate press filter

- Filtering Area

- 20~1000m2

- Product Improvement

- Plastic steel filtering plate, resistance to high temperature and pressure, durable, programmable control, automatic operation

Advantages

Stable performance, high automation, safe and reliable, convenient operation, backwashing operation.

Work Principle

Chamber filter press takes filter cloth as the medium to separate solid and liquid. It is a separating machine with wide rang of particle size. The filter cloth spreads in a filter board surface, it is supported by the swelling groove of filter board, when the filter board is clamped, filter cloth turns to sealing materials, and the cavity between every two filter board forms a separated filter room. During the filter processing, the materials come through the central opening into filter room, the filtrate flow by the feeding pressure, flow out of the filter board after converged. Chamber filter press can be divided into two types according to filtrate discharging ways: open channel flow and under channel flow.

plate and frame press filter separates solid from the liquid in filter form. It is a separating machine with wide rang of particle size. Materials come through the filter room that made up of filter board and filter frame,under the pressure of feeding materials, the filtrate flow through the medium that made up of filter board and filter frame-fiber gap of the filter cloth, arriving at the pattern surface, flow out of the filter board after converged. The solid that left in the filter frame forms filter cake. Plate and frame filter can be divided into two types according to filtrate discharging ways: open channel flow and under channel flow.

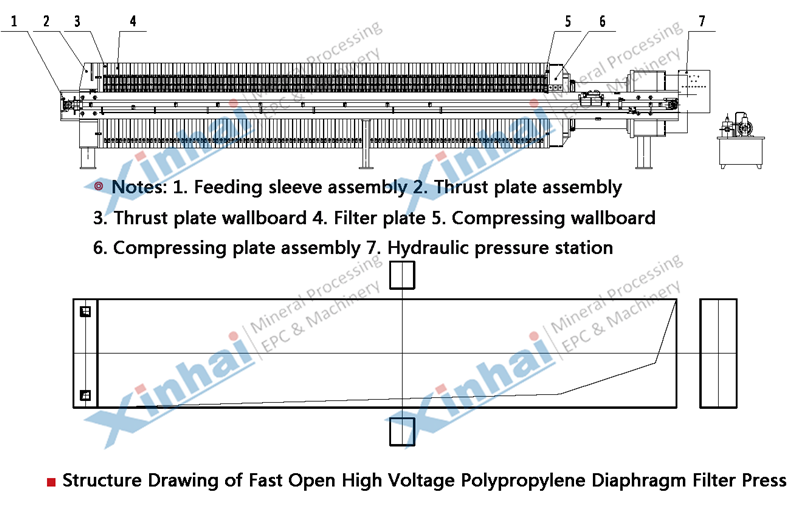

Product Structure

The filtering mechanism consists of filter plate, filter frame, filter cloth and squeezing diaphragm. The two sides of the filter plate is coated by cloth. When squeezing diaphragm need to configure, filter plate consists of diaphragm plate and side plate. Chamber press filter as the left chart shown, plate filter as right chart shown

Widely used in pharmaceutical, chemical industry, metallurgy, standard parts, non-standard screws, dyes, food, brewing, ceramics, oil refining, sewage treatment and other environmental protection industry.

Application of chamber press filter: concentrate filtering, tailings dry stacking, the product particle size reaches -500 mesh

Application of plate press filter:Powder ore dewatering such as gold, silver, copper, iron, zinc and so on; treatment of tailings dam

Technical Parameters

| Model | Filter Area (m2) |

Number of Filter Chamber | Spec. of Membrane Filter Plate (mm) | Filter Cake Thickness (mm) | Volume of Filter Chamber (m3) | Filter Pressure (MPa) |

Overall Dimension (mm) | Capacity (t/h) |

Weight (kg) |

| KZG100/1500-U | 100 | 26 | 1500X1500X90 | 45 | 2.15 | 0.5~1.6 | 8240X3145X2865 | 12 | 23220 |

| KZG150/1500-U | 150 | 38 | 3.17 | 9820X3145X2865 | 18 | 27150 | |||

| KZG200/1500-U | 200 | 52 | 4.37 | 11610X3145X2865 | 24 | 31350 | |||

| KZG250/1500-U | 250 | 64 | 5.39 | 13210X3145X2865 | 30 | 35150 | |||

| KZG150/1600-U | 150 | 34 | 1600X1600X85 | 40 | 2.96 | 0.5~1.6 | 9360X3240X2965 | 18 | 28250 |

| KZG200/1600-U | 200 | 46 | 4 | 10910X3240X2965 | 24 | 32850 | |||

| KZG250/1600-U | 250 | 58 | 5.04 | 12460X3240X2965 | 30 | 37050 | |||

| KZG300/1600-U | 300 | 70 | 6.09 | 14040X3240X2965 | 36 | 40060 | |||

| KZG200/1500X2000-U | 200 | 38 | 1500X2000X95 | 45 | 4.31 | 0.5~1.6 | 10330X3165X3200 | 24 | 35450 |

| KZG250/1500X2000-U | 250 | 48 | 5.48 | 11640X3165X3200 | 30 | 38650 | |||

| KZG300/1500X2000-U | 300 | 58 | 6.65 | 12940X3165X3200 | 36 | 41750 | |||

| KZG350/1500X2000-U | 350 | 68 | 7.82 | 14380X3165X3200 | 42 | 44850 | |||

| KZG300/2000-U | 300 | 44 | 2000X2000X95 | 45 | 6.93 | 0.5~1.6 | 11700X3730X3245 | 42 | 42760 |

| KZG400/2000-U | 400 | 58 | 9.14 | 13500X3730X3245 | 55 | 47960 | |||

| KZG500/2000-U | 500 | 72 | 11.16 | 15530X3730X3245 | 65 | 62980 | |||

| KZG600/2000-U | 600 | 86 | 13.33 | 17510X3730X3245 | 80 | 68020 |

Related Products

Tel: 0086-153-1182-6627

E-mail: mhxu@xinhaimining.net