- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

- Cases

- News

- Contact Us

Home > Beneficiation > Others >Sulphide Minerals Flotation Plant

Sulphide Minerals Flotation Plant

Process Introduction

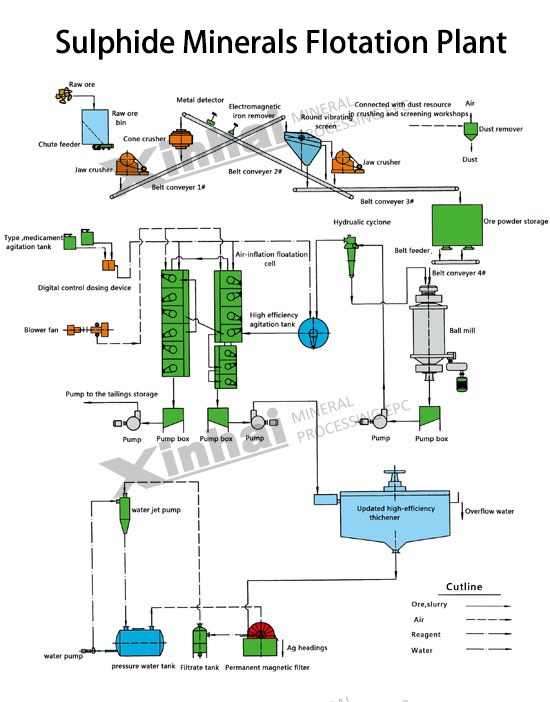

The plant design for froth flotation of sulfide ores depends on its component and ore floatability. After crushing grinding and gravity separation of sulfide ores, the froth flotation plant design is conducted under mineral testing and floatation reagent design.

Application: With 20+Years experience of EPC service & Beneficiation Plant Design. Xinhai Technology Team can dress and process almost all the common sulfide ores, including gold sulfide ore, copper sulfide ore, lead sulfide ore, zinc sulfide ore, iron sulfide ore, nickel sulfide ore, antimony silver sulfide ore. chalcocite, chalcopyrite, galena, molybdenite, pyrite, pyrrhotite, sphalerite and other polymetallic sulfide-bearing ores.

Introduction

Process Flow

Cases

Introduction of Process & Products

Crushing & Grinding

The hard sulphide ores are usually comminuted by autogenous mill and ball mill. Compared to autogenous milling independently, this AG-Ball mill flow design reduce the energy cost and prolong the equipment service life, even doubling the process capacity per day.

As for crushing plant, Xinhai's Hydraulic Cone Crusher take place of the normal jaw crusher. Since the former one shares a higher crushing productivity and improve the crushing performance.

Gravity Separation

With experience in the industry since 1990s, Xinhai has concluded that gravity separation, as an economic pre-treatment method before froth flotation, is suitable for some of the sulfide minerals processing, such as sulfide antimony ores, sulfide tungsten ores and other polymetallic sufide-bearing ores within which consist of large crystal concentrates.Equipment used here are mainly Xinhai jigs, spiral chutes, shaking tables, and other customize gravity separators.

Froth Flotation

The froth flotation and concentration method used exclusively for sulphide ores varies according to the mineral composition and ore floatability. The mainly used design flow is compressed air-pine oil and flotation reagent-foam containing sulfide ore and outlet for gangue.Aside from flotation cell and flotation machines, settling tank, agitation tank is also used during this process.

[Xinhai Beneficiation Plant Design & EPC Service]

Xinhai Devotes to help our customers solve various beneficiation problems, we have set up hundreds of sulphide mineral flotation plants all over the world, including Mongolia 1000tpd Fluorite Plant, Iran 500tpd Galena-Sphalerite Plant, Armenia 1500tpd Pentlandite Plant, Chile 700tpd Chalcopyrite Plant, etc. Xinhai has helped mine owners gain large profit and high return of plant investment over the years.

Xinhai has the most experienced technical support team and the most capable engineers, we are ready to solve any mineral processing problems for you. Contact us here>>

Process Flow

Tanzania 1200tpd Gold Mineral Process Plant

Tanzania 1200tpd gold mineral processing project has finished the installation and commissioning part recently, now has been put into operation, during the installation and commissioning process, Xinhai employees carry forward the work style of working hard and develop the rigorous attitude to guarantee high quality finishment of the work in short period. The production line has got anticipated recovery rate, Xinhai employees got highly appreciated from the customer.

Thickener Construction

Factory Construction

Construction Worker

[Related Process]

Tel: 0086-153-1182-6627

E-mail: mhxu@xinhaimining.net