- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

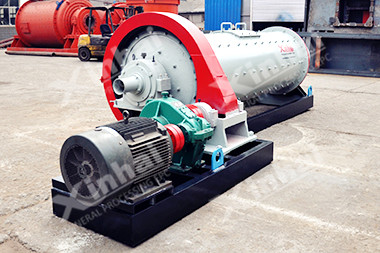

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

- Cases

- News

- Contact Us

Gold CIP Production Line

【Process Introduction】

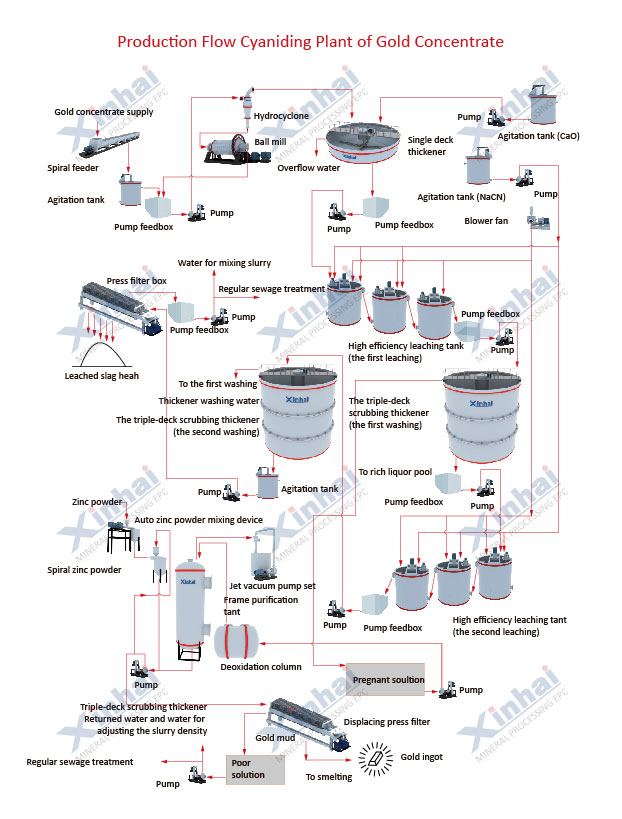

Gold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching pulp.It is very useful gold recovery method in mineral processing.

【Application】

There are two kinds of ore suitable for gold CIP production line: flotation gold concentrate, amalgamation and gravity tailings; mudded oxidized ore

Check Process Flow >>

[Process Description]

gold EPC project in Sudan mainly adopt the method of carbon absorption. This method adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon acid adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon regeneration, leaching pulp, which received a high recovery rate of 92.5%.

Impurity removing of gold CIP production line

Before the adsorption of cyaniding pulp, remove the wood chips to avoid it adsorbs the gold and blocks the carbon screen.

Leaching and adsorption of gold CIP production line

Adding carbon in the leaching tank; the carbon absorbs gold becoming gold loaded carbon. After adsorption, carbon screen separates the carbon and pulp.

Desorption electrolysis of gold CIP production line

Under high temperature and pressure, gold loaded carbon separates gold mud and carbon in closed system

Smelting of gold CIP production line

After simple pickling and impurity removal, the gold ingots are obtained

Desorption electrolysis system with high efficiency, low energy consumption and fast

Under the high temperature and pressure, this system has advantages of no cyanide, automatic controlling, high efficiency, fast and low energy consumption.

High Efficiency: When the grade of gold loaded carbon reaches 3000g/t, desorption rate can reach more than 96%.

Fast: due to the high temperature and pressure, the time of desorption electrolysis is 12 hours shortened by 50-70%

Low energy consumption: due to the same temperature and fast working, the energy consumption is 1/2-1/4 of regular system

No cyanide: without adding NaCN in desorption solution, low cost and no pollution

High grade gold mud, extract gold mud easily

Automatic control: installed level liquid control system, temperature control system, automatic control system

Safety: With three security measures, system intelligent, automatic limit pressure and pressure release mechanism, safety valve

[Related Products]

[ Process Flow ]