- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

- Cases

- News

- Contact Us

Gold CIL Processing Line

【Process Introduction】

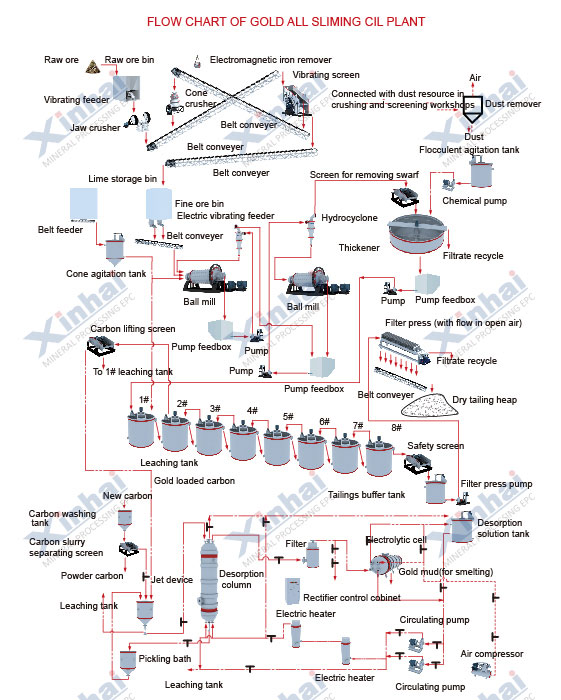

Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%. It has become the first choice of modern gold mining and beneficiation plant design.

【Application】

CIL mainly applies for the process of above 1g/t grade gold ore and gold ore with large bearing ore volume: silver, platinum, copper, etc. As CIL sees a better performance in extracting these minerals at the same time. And Mineral Dressing Test Center can help you with the component testing of your ores.Check Process Flow >>

【Flow Design Equipments】

After Crushing and Comminution, add the gold ore slurry into 9 Leaching Agitation Tanks, pour in cyanide solution in the first 2 tanks and Activated Carbon in the following 7 tanks for the reverse-absorption process--This design shortens the time period of gold staying in the cyanide pregnant solution and recovers gold in advance, which sees a faster investment return compared to other designs.

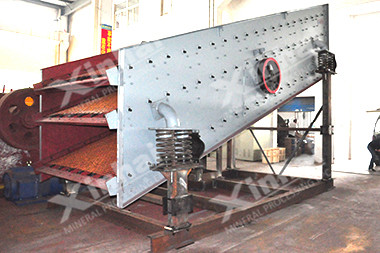

Filter Press and Vibrating Screen is needed in gold ore slurry reverse-transmission process.

we have a design that ensures the minimum carbon gold loses during transmission. It lower the gold loses and the processing line is easy to maintain.

After the carbon leaching and Elution of gold, NaCN and NaOH solution is used for removing the gold from loaded carbon at a high temperature. Then the loaded solution passes through the electro winning cell and the metals are attached to cathodes.

Desorption Electrolysis System can successfully aggregate these steps in one processing unit, the pure gold and other useful metals are highly attained via this system.

【Project Cases】

The latest CIL Plant we have constructed locates in Tanzania, we brought up a satisfying 1200tpd project with the mine owner from Tanzania Bulsowa Mining Co., Ltd. View Project Case Here

【What We Do】

Bringing mine owners LARGE profits, we have set up over 50+ gold CIL plants worldwide and build a reputation in the field of mineral processing technology since 1997. our provides Whole Line Plant & Design Personnel Training, helping mine owners with Equipment Procurement and Construction from ore to pure gold. About our EPC Service, check out EPC Service Here[Related Products]

[ Process Flow ]