- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

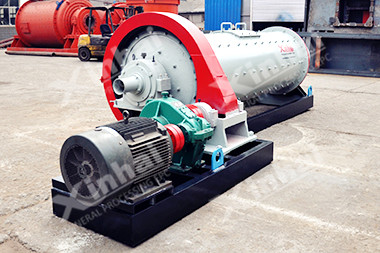

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

- Cases

- News

- Contact Us

Kaolin Mining Process

【Process Introduction】

Dry & wet separation are the two main Kaolin mining process . Dry separation process is used to process Kaolin ore with higher white degree and lower sand and gravel content, this process characterized by easy operation and saving cost. Kaolin raw ore being crushed in Kaolin crusher, then the Kaolin concentrate can be get after being grinded in raymond mill. Wet Kaolin mining process is used to process complex Kaolin mine. our wet separation process applying high gradient magnetic separation(HGMS), froth flotation and selective flocculant to make full use of Kaolin mine resources.

【Application】

Kaolin wet process is suitable for Kaolin mine with soft texture and high brightness.

Check Process Flow >>

【Process Description】

High Gradient Magnetic Separation (HGMS)

HGMS is used to process kaolin mine with staining impurities such as hematite, which can efficiently remove impurities so as to improve brightness and quality of the kaolin concentrate.

Froth Flotation

Flotation separation is used to remove titanium ore that is in the form of silicas. Applying calcite and silica sand as carrier to increase the ion kinetic energy. Flotation cell is the main kaoling mining machines of this part.

Selective Flocculant Process

Applying polymer flocculatant as kaolin mining selective flocculant. kaolin mine will sink to the bottom while titanium ore suspend in the upper showing red brown, thus we can use magnetic separation to process kaolin mine.

【What We Do】

Bringing mine owners LARGE profits, we have set up over 50+ gold CIL plants worldwide and build a reputation in the field of mineral processing technology since 1997. our provides Whole Line Plant & Design Personnel Training, helping mine owners with Equipment Procurement and Construction from ore to pure gold. About our EPC Service, check out EPC Service Here

[Related Products]

[ Process Flow ]