- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

- Cases

- News

- Contact Us

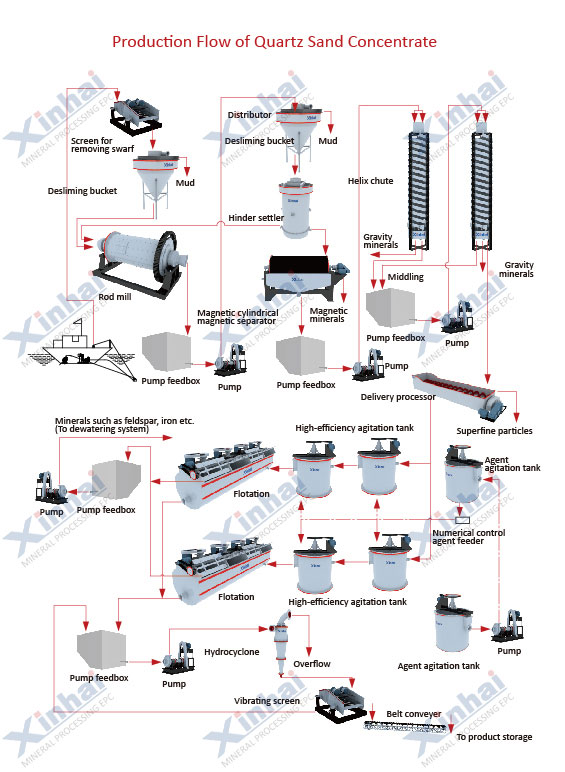

Quartz Sand (Silica Sand) Dressing Production Line

【Process Introduction】

Quartz sand (silica sand) purification is removal of a small amount of impurities and the high difficulty separation technique to obtain refined quartz sand (silica sand) or high purity quartz sand (silica sand). The purification technologies of quartz sand (silica sand) at home and abroad are washing, classifying & desliming, scrubbing, magnetic separation, flotation, acid leaching, microbial leaching, etc.

【Application】

Quartz sand (silica sand) Dressing Production Line is suitable for quartz sand containing iron or mica.

Check Process Flow >>

[Process Description ]

Washing and classifying desliming

The SiO2 grade in quartz sand (silica sand) decreases by quartz sand size becoming finer, so washing and desliming of crude quartz sand (silica sand) is necessary before next step.

Scrubbing

Scrubbing is the way to remove film iron and impurity minerals on the surface of quartz by mechanical force and crush these mineral aggregate. The quartz sand (silica sand)gets further purification by classification. There are two kinds of methods rob scrubbing and mechanical scrubbing.

Flotation

The separation of mica and quartz is difficult, the effective methods: anionic collector in acid condition and anionic - cationic collector in alkaline condition. The purification of quartz sand (silica sand) can reach 99% after scrubbing, desliming, magnetic separation and flotation.

Acid Leaching

Dilute acid had a significant effect on removing iron and aluminum, and concentrated acid for the removal of titanium and chromium, and mixed acid for mineral impurity. Control various factors of acid leaching should be based on quartz final grade requirements, and as far as possible reduce the acid concentration, temperature and dosage to achieve quartz purification.

[ Case ]

A quartz sand (silica sand) dressing plant in Yunnan with the main component was quartz sand accounting for 95-97%; siliceous cement accounting for 8-23%, the impurity minerals were hematite, limonite, etc. accounting for about 1-3%. The plant adopted screen classification - dry magnetic separation - dosing strong scrubbing-flotation process, the final indexes: SiO2 ≥ 97.62%, Fe2O3 ≤ 0.24, Al2O3 ≤ 1.11%.The poor indexes seriously affect the production and economic benefit. Therefore, the plant commissioned to reform technology. By dressing tests, we decided to adopt the screen classification - dry magnetic separation - dosing strong scrubbing - acid leaching process, specific index comparison as follow:

| Comparison of Reformation | Process | Concentrate Index |

| Before Reformation | screen classification - dry magnetic separation - dosing strong scrubbing-flotation process | SiO2≥97.62%,Fe2O3≤0.24,Al2O3≤1.11% |

| After Reformation | screen classification - dry magnetic separation - dosing strong scrubbing - acid leaching process | SiO2≥99.4%,Fe2O3≤0.052,Al2O3≤0.048% |

After the technical reformation, the purified quartz sand (silica sand) met the quality requirements of silicon powder, and it can be used in ceramic, paint, metal casting industry after the superfine grinding.

[Related Products]

[ Process Flow ]