- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

- Cases

- News

- Contact Us

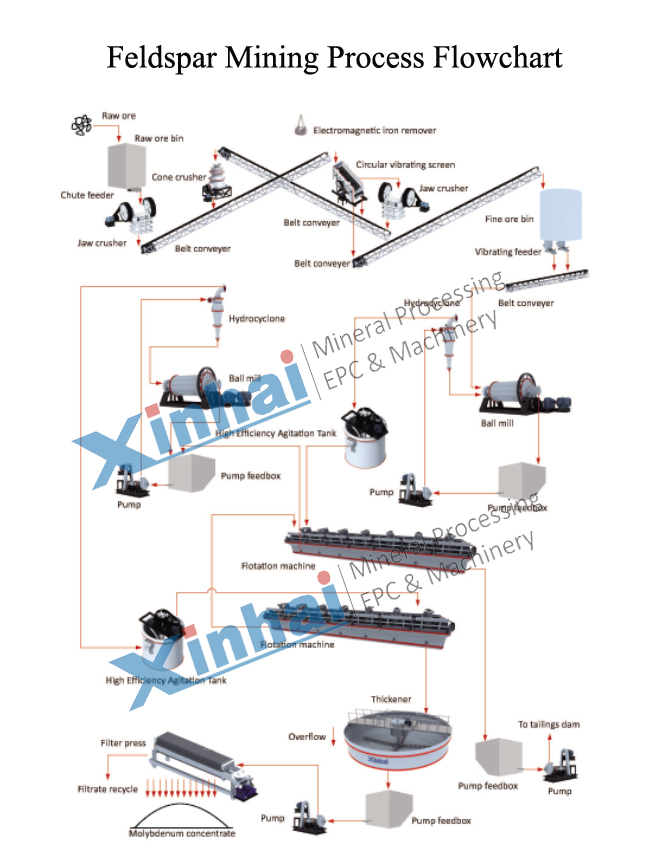

Feldspar Mining Process

【Process Introduction】

Feldspar is a kind of silicate minerals which contains calcium, sodium and potassium, there are many categories of Feldspar including albite, anorthite, etc. Feldspar mining process mainly applying flotation process, and Feldspar mining machines mainly including jaw crusher, ball mill, spiral chute, and concentrating table, etc.

Check Process Flow >>

[Process Introduction]

Crushing & Grinding

Large particle size of feldspar ore firstly should be crushed by jaw crusher to qualified particle size, thus to guarantee the grinding quality and protect ball mill.

Ball mill is applied into the second stage – grinding, we have wet grate ball mill and wet grate overflow ball mill which can perfectly grind feldspar ore into qualified particle size.

Flotation Separation

With experience in Feldspar flotation separation, flotation cell is the main mining machines in this part, the slurry dealt with agential through milling and inflating can make certain particles of it selectively attaches to the bubbles to achieve mineral separation.

Besides flotation machines, other mining machines also will be used in the stages, if you want to know more, just click the online service.

Special Report:Beneficiation Plant Design & EPC Service

We Devotes to help our customers solve various beneficiation problems, we have set up hundreds of sulphide mineral flotation plants all over the world, including Mongolia 1000tpd Fluorite Plant, Iran 500tpd Galena-Sphalerite Plant, Armenia 1500tpd Pentlandite Plant, Chile 700tpd Chalcopyrite Plant, etc. we have helped mine owners gain large profit and high return of plant investment over the years. we have the most experienced technical support team and the most capable engineers, we are ready to solve any mineral processing problems for you.

[Related Products]

[ Process Flow ]