- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

- Cases

- News

- Contact Us

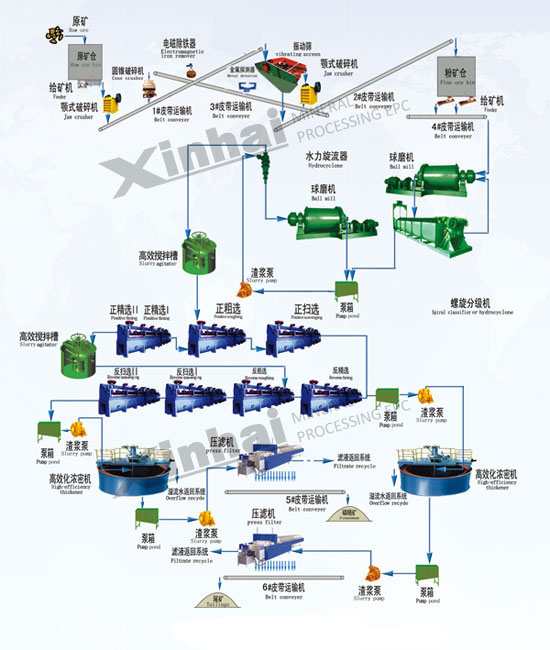

Phosphorite (Phosphate) Flotation Equipment Production Line

【Process Introduction】

According to different ore properties of phosphorite (phosphate), We designs many processes for it such as flotation, gravity separation, chemical leaching, combined dressing, photoelectric sorting, etc. Flotation is widely used in phosphorite (phosphate) including direct flotation, reverse flotation, reverse flotation and flotation, and double-reverse flotation process.

【Application】

Phosphorite (phosphate) Flotation Product Line is applied for complex structure phosphorite (phosphate) with fine particle distribution, closed embeddedness relationship, difficult monomer dissociation, etc.

Check Process Flow >>

[Process Description ]

Flotation process

Direct flotation inhibits gangue minerals by effective inhibitors, and the phosphorus mineral is enriched in foam by collecting agent. This process is suitable for low grade phosphorite (phosphate) ores including magmatite type apatite and sedimentary metamorphic type phosphorite (phosphate) ore

Reverse Flotation Process

Mainly used for the separation of phosphorite (phosphate) and dolomite; dolomite is collected with fatty acid collector in weak alkaline medium, and the phosphorus mineral is enriched in the groove. The biggest advantage of reverse flotation process is the realization of the normal temperature flotation.

Double-Reverse Flotation Process

In alkaline conditions, double-reverse flotation makes the silicate surface positively charged, and the anionic collector separates minerals meaning floating dolomite firstly, and then reverse floating silicate; the product is heavy concentrate in groove; the production line can be carried out at normal temperature and coarse grain condition.

[ Case ]

A phosphorite in Yunnan belonged to low grade siliceous and calcareous collophanite with fine particles and close distribution of useful minerals and gangue minerals. The plant adopted flotation and reverse flotation process, but there were some defects in the flotation reagent dosage and high temperature. In order to reduce the cost, the plant authorized us to take technical reformation. we used the double reverse flotation for phosphorite after the test. we achieved 40% concentrate grade when the crude ore grade was 18.55%. Indexes comparison as follow:

| Comparison of Reformation | Process | Grade of Phosphorite (Phosphate) Concentrate /% | Recovery Rate of Phosphate Concentrate /% |

| Before Reformation | Flotation and Reverse Flotation Process | 29.74 | 70.27 |

| After Reformation | Double-Reverse Flotation Process | 32.58 | 72.18 |

By this technical reformation, the technology principle was more reasonable; the non-alkali process, no pollution to the environment; the normal temperature condition could effectively reduce the cost.

[Related Products]

[ Process Flow ]