- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

- Cases

- News

- Contact Us

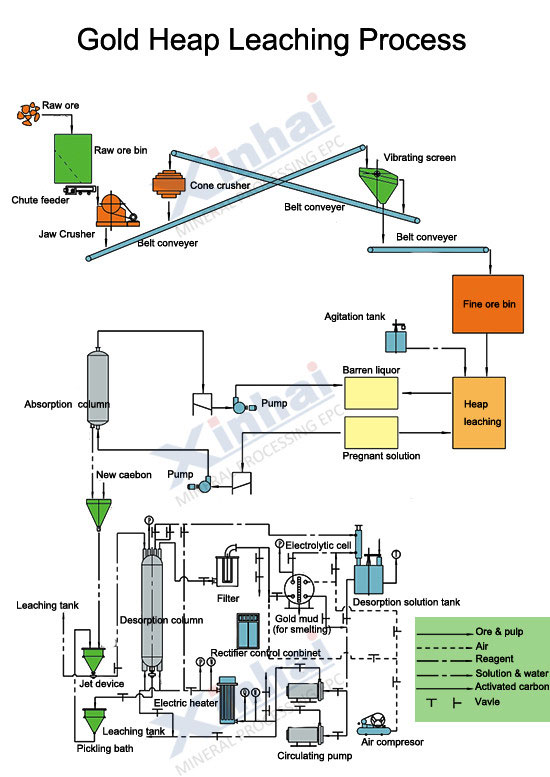

Gold Heap Leaching Process

【Process Introduction】

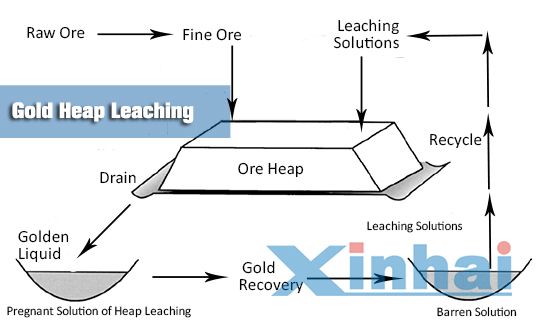

Heap leaching (HL) is a flexible and economic mineral processing method, commonly used to extract gold from low-grade gold ores. In this process, ore is firstly crushed to fine particles. By spraying leaching solution to the large piles, the gold-containing solution is leached. Then used the method of carbon adsorption, zinc powder displacement device and so on to separate gold from the liquid.

【Application】

Heap leaching method is always used for low-grade ore, small gold mine, or both. These ore can not to process by using the conventional method.

Check Process Flow >>

[Advantages]

Simple process, less equipment;

Small investment, yield quick returns, and low cost;

The nature, grade, quantity of ore has strong adaptability.

[Process Description]

The heap leaching plant adapt to local condition. According to the feature of the landscape, we can built permanent heap plant or overlap-type heap plant. If the slope was not steep with open views, permanent heap plant is suitable.

Raw Ore Treatment

The raw ore is crushed into fine particles (30-50mm) by using jaw crusher or cone crusher produced by us, then will be heap leaching directly; or pelletization (fine particles are pelletized into bigger lumps ), then piled by forklift.

Heap Spraying

Then the large piles will be sprayed by the leaching solutions, through which the gold-containing solution will be leached from the piles. The pregnant liquid will flow into pregnant solution pool. Then used the method of carbon adsorption, zinc powder displacement device and so on to separate gold from the liquid. The tail liquid will be recycled.

Desorption Electrolysis System

The video is desorption electrolysis system Tanzania gold project. Desorption electrolysis system is one of the key decive in CIP. In gold electrowinning process, when the electrolysis equipment is added with anions which are more easily absorbed by activated carbons, Au(CN)2ˉ is replaced by anion and the gold desorption is achieved. After the carbons loaded with gold are desorbed, pregnant solution is process via ionization. At last, solid gold is attained.

[Related Products]

[ Process Flow ]